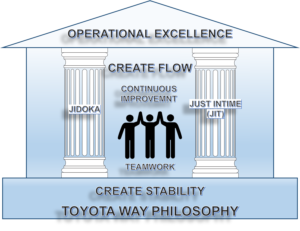

Building the "Toyota Production System House"

At Collis Consulting, our approach is based on building the Toyota Production System House, which encompasses the core principles of the Toyota Way. We collaborate with your team to develop a solid foundation focused on continuous improvement, respect for people, and the pursuit of excellence. We help you establish the pillars of Just-in-Time, Jidoka (Autonomation), and Standardized Work, creating a sustainable framework for operational excellence. Our aim is to guide your organization to achieve world-class performance and a competitive edge in the market.

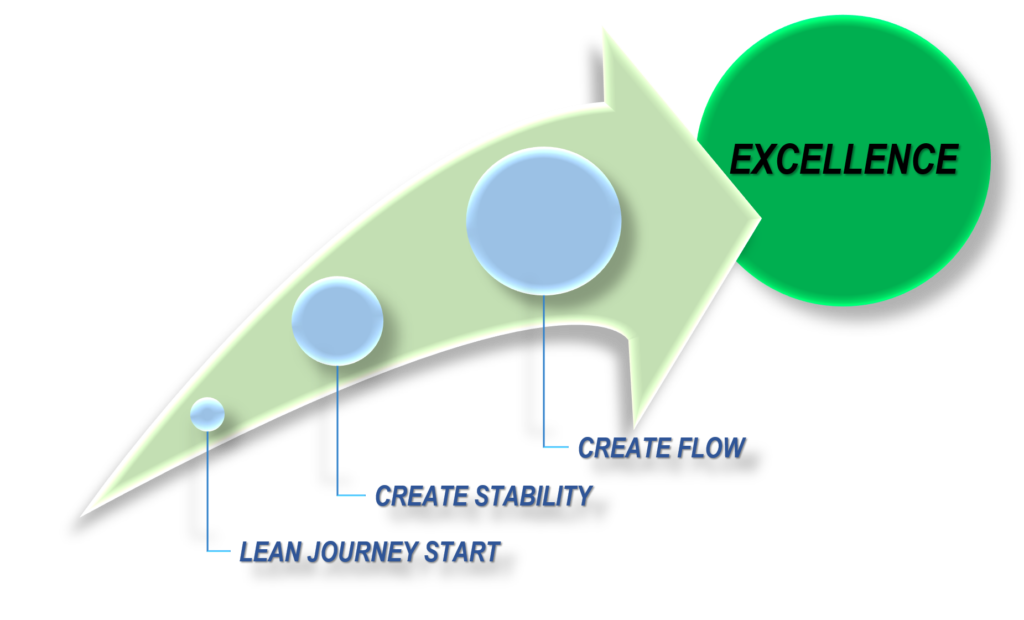

Collis Journey to Excellence

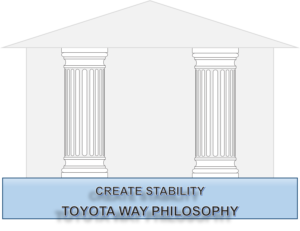

Creating Stability - The Foundation

The foundation is built on the principle of creating stability. At the core of our approach, with “safety first“ mindset, we prioritize visual management, ensuring that abnormalities are immediately visible in the workplace. This allows us to swiftly identify and address any issues, maintaining a smooth and efficient operation.

We understand the significance of stable and standardized processes. By establishing clear and consistent procedures, we minimize variations and optimize productivity. This standardization ensures that our team members can perform their tasks effectively and efficiently, reducing errors and improving overall quality.

Heijunka, or leveled production, is another key aspect of our system. We strive to achieve a balanced production flow to meet customer demand. This eliminates overburdening and uneven workloads, resulting in smoother operations and improved customer satisfaction.

We strongly believe in the importance of people training, participation, motivation and engagement. Team members equipped with the necessary skills and knowledge will excel in their roles. They are encouraged to actively contribute ideas and suggestions, fostering a culture of continuous improvement. By valuing our people and providing opportunities for growth, we create a motivated workforce that is dedicated to delivering excellence.

Above all, we have a customer-first priority mindset. Understanding and exceeding customer expectations drives everything we do. We actively listen to their needs, anticipate future demands, and strive to provide products and services of exceptional quality. Our commitment to customer satisfaction is at the forefront of our operations.

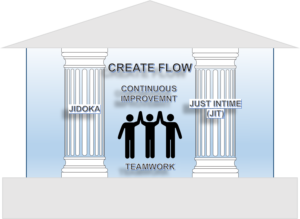

Creating Flow

The 2 pillars are built on the principle of creating flow and drive operational excellence.

Jidoka, the first pillar, enables us to make problems visible and solve them swiftly. By implementing concepts such as automatic stops, andon, person-machine separation, poka-yoke (error-proofing), in-station quality control, and problem-solving methodologies, we ensure that issues are identified at the source. Jidoka empowers our team to take ownership, fostering a culture of continuous improvement and problem-solving rooted in identifying and addressing the root cause.

The second pillar, JIT, focuses on delivering the right part, right amount, at the right time. With takt time planning, continuous flow, pull systems, quick changeover, small lot sizes, kanban systems, one-piece flow and optimized workplace layouts, we eliminate waste and enhance efficiency. Our integrated logistics and emphasis on the right timing enable us to streamline processes, reduce lead times, and exceed customer expectations.

At the heart of these pillars are our people, continuously striving for improvement. With clear common goals and a commitment to “safety first“ mindset and waste elimination through genchi genbutsu (go and see), problem-solving methodologies (PDCA) and continuous training, our team drives excellence. We recognize and celebrate their achievements, fostering a culture of recognition and empowerment.

Collis Consulting will strongly help your company to harness the power of Jidoka and JIT, together with your dedicated team, to create flow, eliminate waste, and drive sustainable success. Together, we will optimize operations, exceed customer expectations, and continuously improve towards operational excellence.

Excellence

Achieving excellence in lean manufacturing culture implementation, where we reach new heights in quality, lead time, safety, and the morale of our people.

At the roof of “The House of TPS – Toyota Way,” we embody the essence of excellence. We have mastered lean manufacturing principles to deliver the best quality products and services, ensuring customer satisfaction and loyalty. Our streamlined processes and continuous improvement efforts result in the shortest lead times, enabling you to respond swiftly to market demands.

Safety is our utmost priority. We have cultivated a safety-centric culture that safeguards your people and assets. By implementing robust safety practices and protocols, we create an environment where everyone feels secure and valued.

The success is attributed to the highly motivated and engaged workforce. Company prioritize the morale and well-being of people, fostering a positive and inclusive culture that encourages collaboration, innovation and personal growth. We believe that a happy and empowered team drives extraordinary results.

Even at this level of excellence, people remain committed to continuous improvement. Through kaizen activities, they continuously seek opportunities to optimize processes, eliminate waste and drive innovation. The dedication to kaizen ensures that company stay at the forefront of industry trends and maintain our position as a leader in lean manufacturing.

Collis Consulting will sustainably guide your organization to the roof of “The House of TPS – Toyota Way.” Our goal is to help you to achieve the industry’s global benchmark and beyond.